As an automotive suspension specialist who has spent over 15 years analyzing damping technologies across various vehicle platforms, I frequently encounter drivers struggling to choose between gas and oil shock absorbers. This decision significantly impacts your vehicle’s performance, comfort, and long-term maintenance costs. Today, I’ll break down the fundamental differences between these two technologies and help you determine which option best suits your specific driving needs and vehicle requirements.

Understanding Shock Absorber Fundamentals

Before diving into the gas versus oil comparison, it’s essential to understand that both systems use hydraulic fluid for damping. The key difference lies in how each system manages fluid displacement, prevents cavitation, and maintains consistent performance under varying conditions.

The Physics of Hydraulic Damping

All shock absorbers operate on the principle of controlled fluid displacement through calibrated orifices. As your vehicle encounters road irregularities, the piston moves within the cylinder, forcing hydraulic fluid through precisely engineered valving systems that convert kinetic energy into thermal energy.

Core Components Include:

- Piston assembly with compression and rebound valving

- Hydraulic fluid providing the damping medium

- Cylinder housing containing the fluid and piston

- Mounting hardware connecting to vehicle suspension points

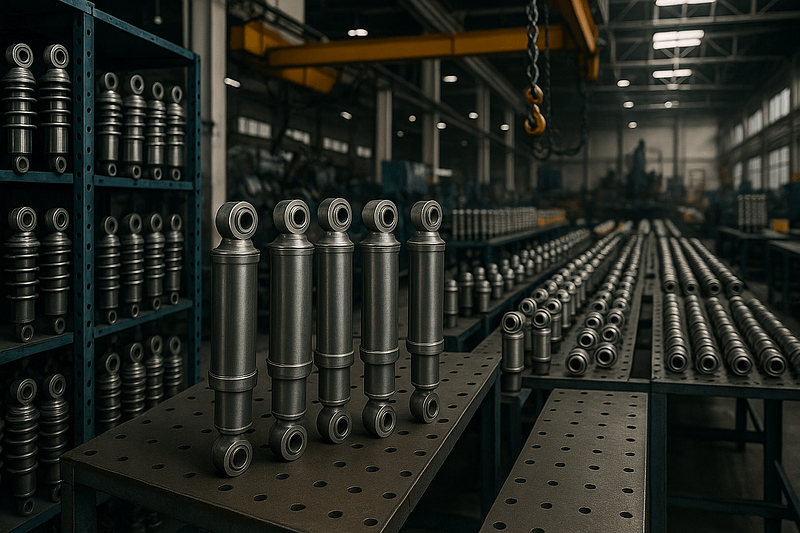

Oil Shock Absorbers: Traditional Hydraulic Technology

Twin-Tube Oil Shock Construction

Conventional oil shock absorbers utilize a twin-tube design featuring an inner working cylinder surrounded by an outer reservoir tube. This configuration has dominated the automotive market for decades due to its cost-effectiveness and reliable performance in standard driving conditions.

Design Characteristics:

- Inner cylinder houses the piston and primary damping action

- Outer reservoir stores excess fluid during compression cycles

- Base valve controls fluid flow between chambers

- Hydraulic oil provides damping medium without pressurization

Performance Characteristics of Oil Shocks

Advantages of Oil-Based Systems:

Cost Effectiveness: Oil shock absorbers represent the most economical damping solution, typically costing 30-50% less than equivalent gas-charged systems.

Smooth Operation: At moderate speeds and normal driving conditions, oil shocks provide excellent ride comfort with progressive damping characteristics that many drivers prefer for daily commuting.

Proven Reliability: Decades of development have refined oil shock technology, creating highly reliable systems with predictable maintenance intervals and well-understood failure modes.

Simple Maintenance: Oil shock absorbers feature straightforward construction that simplifies diagnosis and repair procedures.

Limitations of Oil Shock Technology

Temperature Sensitivity: Oil-based systems experience performance degradation as operating temperatures increase, leading to reduced damping effectiveness during aggressive driving or extended highway use.

Cavitation Issues: Under rapid compression cycles, oil can develop air bubbles (cavitation) that compromise damping consistency and create unpredictable handling characteristics.

Fade Characteristics: Extended use generates heat that causes oil viscosity changes, resulting in damping fade that affects vehicle stability and control.

Limited Performance Range: Oil shocks work well within narrow operating parameters but struggle to maintain consistency across diverse driving conditions.

Gas Shock Absorbers: Pressurized Performance Technology

Gas-Charged System Architecture

Gas shock absorbers incorporate pressurized nitrogen gas to enhance performance and eliminate the limitations inherent in conventional oil systems. This technology represents a significant advancement in damping consistency and thermal management.

Construction Elements:

- Pressurized nitrogen charge (typically 100-360 PSI)

- Floating piston separating gas and oil chambers

- Enhanced sealing systems maintaining pressure integrity

- Advanced valving optimized for pressurized operation

Gas Shock Performance Advantages

Cavitation Prevention: The pressurized gas charge prevents hydraulic fluid aeration by maintaining positive pressure throughout the entire operating range, ensuring consistent damping performance.

Temperature Stability: Gas-charged systems maintain damping characteristics across broader temperature ranges, providing consistent performance from cold startup to high-temperature operation.

Improved Response: Pressurization enhances damping response time, creating more precise vehicle control during dynamic driving situations.

Extended Performance Range: Gas shocks maintain effectiveness across diverse driving conditions, from city commuting to aggressive highway driving.

Types of Gas Shock Systems

Low-Pressure Gas Systems (100-150 PSI):

- Application: Standard passenger vehicles

- Benefits: Improved consistency over oil shocks

- Cost: Moderate premium over conventional oil systems

High-Pressure Gas Systems (200-360 PSI):

- Application: Performance vehicles and heavy-duty applications

- Benefits: Maximum damping consistency and heat resistance

- Cost: Premium pricing reflecting advanced technology

Monotube Gas Designs:

- Construction: Single-tube with floating piston separator

- Advantages: Superior heat dissipation and performance consistency

- Applications: High-performance and racing applications

Comparative Performance Analysis

Daily Driving Conditions

Urban Commuting (0-35 MPH):

- Oil Shocks: Excellent comfort and smooth operation

- Gas Shocks: Slightly firmer but more consistent response

- Recommendation: Either technology suitable, cost may determine choice

Highway Cruising (55-80 MPH):

- Oil Shocks: Adequate performance with potential fade during extended use

- Gas Shocks: Superior consistency and stability at sustained speeds

- Recommendation: Gas systems preferred for frequent highway driving

Performance Driving Scenarios

Aggressive Cornering and Acceleration:

- Oil Shocks: Performance degradation under stress, potential fade

- Gas Shocks: Maintained damping control throughout performance envelope

- Clear Winner: Gas technology for performance applications

Towing and Heavy Loading:

- Oil Shocks: Compromised performance under increased loads

- Gas Shocks: Enhanced load-carrying capability with maintained control

- Recommendation: Gas systems essential for towing applications

Climate and Environmental Considerations

Extreme Temperature Operations:

Cold Weather Performance:

- Oil Shocks: Potential stiffness during cold startup

- Gas Shocks: More consistent operation across temperature ranges

- Advantage: Gas systems for extreme climate conditions

High-Temperature Environments:

- Oil Shocks: Significant performance degradation and fade

- Gas Shocks: Maintained damping effectiveness and control

- Clear Choice: Gas technology for hot climates

Vehicle-Specific Recommendations

Compact and Mid-Size Sedans

Typical Requirements:

- Primary Use: Daily commuting and occasional highway travel

- Priority: Comfort, fuel economy, and cost-effectiveness

- Recommendation: Quality oil shocks for budget-conscious buyers, low-pressure gas for enhanced consistency

Optimal Choice: Low-pressure gas systems provide the best balance of performance and cost for most sedan applications.

SUVs and Light Trucks

Performance Demands:

- Load Carrying: Frequent passenger and cargo hauling

- Versatility: Mixed city and highway driving conditions

- Stability: Enhanced control for higher center of gravity

- Recommendation: Gas-charged systems for improved load handling and stability

Performance and Sports Vehicles

Critical Requirements:

- Precision Control: Exact damping for performance driving

- Heat Management: Consistent operation under stress

- Response Time: Immediate damping adjustments

- Mandatory Choice: High-pressure gas or monotube systems

Commercial and Heavy-Duty Applications

Demanding Conditions:

- Constant Loading: Regular heavy cargo transport

- Extended Operation: Long-duration highway use

- Durability: Resistance to wear and environmental factors

- Essential Technology: Heavy-duty gas systems with enhanced construction

Cost-Benefit Analysis

Initial Investment Comparison

Oil Shock Absorber Costs:

- Budget Systems: $50-100 per unit

- Premium Oil Shocks: $100-200 per unit

- Installation Labor: $200-400 for complete vehicle

Gas Shock Absorber Costs:

- Low-Pressure Gas: $100-200 per unit

- High-Pressure Systems: $200-400 per unit

- Installation Labor: $200-400 for complete vehicle

Long-Term Value Considerations

Oil Shock Total Cost of Ownership:

- Replacement Interval: 50,000-70,000 miles

- Performance Degradation: Gradual decline requiring earlier replacement

- Related Component Wear: Potential accelerated tire and suspension wear

Gas Shock Total Cost of Ownership:

- Replacement Interval: 70,000-100,000 miles

- Maintained Performance: Consistent operation throughout service life

- System Protection: Reduced wear on related suspension components

Return on Investment Analysis

The premium cost of gas shock absorbers typically pays for itself through:

- Extended Service Life: 20-40% longer replacement intervals

- Improved Fuel Economy: Better vehicle stability reduces rolling resistance

- Tire Life Extension: Consistent damping prevents irregular wear patterns

- Enhanced Safety: Superior performance in emergency situations

Installation and Maintenance Considerations

Professional Installation Requirements

Oil Shock Installation:

- Complexity: Standard procedures with conventional tools

- Time Requirements: 2-4 hours for complete vehicle

- Special Considerations: Proper torque specifications and alignment

Gas Shock Installation:

- Pressurization Handling: Requires careful pressure system management

- Specialized Tools: May require specific equipment for high-pressure systems

- Safety Protocols: Enhanced precautions for pressurized components

Maintenance and Service Intervals

Oil Shock Maintenance:

- Inspection Frequency: Every 12,000-15,000 miles

- Common Issues: Fluid leaks and gradual performance degradation

- Service Indicators: Visual inspection and bounce test evaluation

Gas Shock Maintenance:

- Inspection Frequency: Every 15,000-20,000 miles

- Monitoring Requirements: Pressure integrity and seal condition

- Performance Testing: Professional diagnosis for optimal assessment

Making the Right Choice for Your Vehicle

Assessment Criteria Framework

Driving Pattern Analysis:

- Daily Mileage: High-mileage drivers benefit from gas technology

- Route Types: Mixed city/highway favors gas systems

- Load Requirements: Regular hauling demands gas-charged systems

- Performance Expectations: Aggressive driving requires gas technology

Budget Consideration Matrix:

- Initial Cost Sensitivity: Oil shocks for immediate budget relief

- Long-Term Value Focus: Gas systems for total ownership cost optimization

- Performance Priority: Gas technology regardless of cost premium

Vehicle Age and Condition Factors

Newer Vehicles (0-5 years):

- Recommendation: Gas systems to maintain optimal performance

- Rationale: Preserve vehicle value and safety systems integration

Mid-Age Vehicles (5-10 years):

- Evaluation: Consider remaining service life and usage patterns

- Recommendation: Gas systems for high-use vehicles, oil for limited use

Older Vehicles (10+ years):

- Assessment: Balance repair costs with remaining vehicle value

- Pragmatic Choice: Quality oil shocks often sufficient for limited remaining service

Future Technology Trends

Emerging Shock Absorber Technologies

Adaptive Damping Systems:

- Integration: Electronic control with gas-charged technology

- Benefits: Real-time damping adjustment for optimal performance

- Applications: Luxury and performance vehicle segments

Magnetic Ride Control:

- Technology: Magnetorheological fluid damping systems

- Advantages: Instantaneous damping characteristic changes

- Market Position: Premium applications with gas backup systems

Conclusion: Optimizing Your Suspension Investment

After analyzing thousands of shock absorber installations and performance evaluations, my professional recommendation strongly favors gas-charged shock absorber technology for most modern vehicle applications. While oil shocks remain viable for specific budget-conscious scenarios, the performance advantages, longevity, and safety benefits of gas systems justify the moderate cost premium.

Choose Gas Shock Absorbers If:

- You drive more than 15,000 miles annually

- Your vehicle regularly carries loads or passengers

- You frequently encounter varied driving conditions

- Long-term value and performance matter more than initial cost

- You prioritize safety and vehicle stability

Consider Oil Shock Absorbers If:

- Your vehicle has limited remaining service life

- Budget constraints require immediate cost minimization

- Driving patterns involve primarily low-speed city commuting

- Vehicle usage is minimal (under 8,000 miles annually)

The suspension system represents one of your vehicle’s most critical safety and performance components. Investing in appropriate shock absorber technology ensures optimal vehicle control, passenger comfort, and long-term reliability. Whether you choose gas or oil technology, prioritize quality components from reputable manufacturers and professional installation to maximize your investment value.

Remember: Your shock absorbers affect every aspect of vehicle performance – from daily comfort to emergency braking capability. Choose wisely, maintain properly, and enjoy the confidence that comes with optimal suspension performance.